A Swing to Keep Chips in Check

Prevents Chips

from Becoming Entangled

Innovates Productivity and Work Processes

- A Swinging Nozzle - Wavy Nozzle

The technologies of MinebeaMitsumi

? an integrated manufacturer of high-precision components

- leads customers to business success

Have you ever had these problems?

Damage to products!

Defect rate of even a few percent results in a big loss!

Something needs to be done!

Breakdown of cutting tools

Isn’t there a way to extend tool life and reduce costs?

Accuracy isn’t consistent!

Leftover chips during cutting need to be reduced!

Manpower for checking also needs to be reduced!

Cleaning is necessary!

It's automated but still needs to be stopped for cleaning!

The automated line has to be halted!

Chips are obstructing automated conveyance lines!

Something needs to be done!

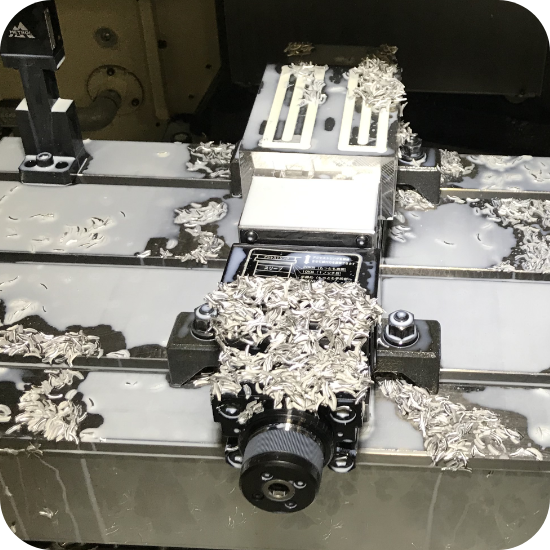

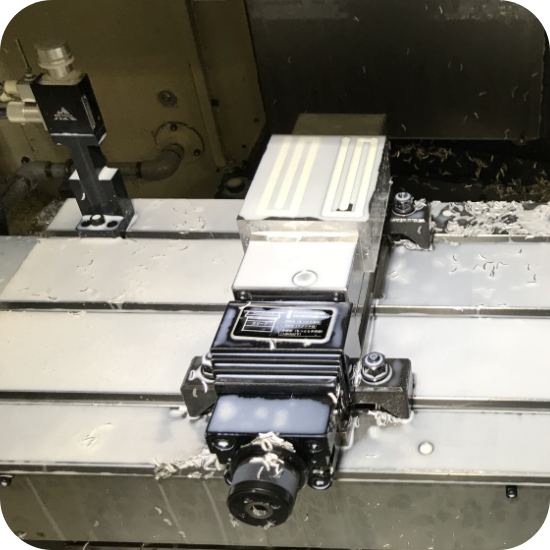

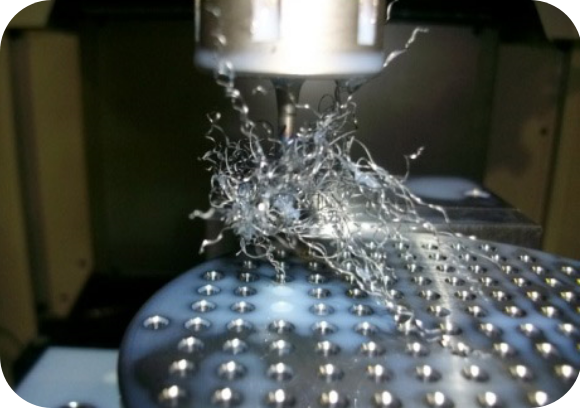

This swinging nozzle sprays coolant and air, blowing away chips from the machining area.

- Damage to products

- Defective cutting/accuracy

- Blade/tool breakdown

- Machining stoppage

for chip removal

The solution to problems caused by chips.

-

FEATURE

01 -

FEATURE

02 -

FEATURE

03

Reasons Why Wavy Nozzle is Chosen

Swinging nozzleeffectively removes chips near machining area

Markedly transforms productivity at component machining sites and work processes.

*Machining with air blow

Chips don't become entangled/accumulated

Increased machine operating efficiency and productivity

Increased machine operating efficiency and productivity

- BEFOREMachines need to be stopped to clean out chips!

- AFTERMachine stoppage frequency reducedContinuous automatic operation realized!

- BEFOREThe automatic line keeps stopping!

- AFTERError reduction during robot conveyancePromotes unmanned operations!

Fixed nozzle use

Chips are scattered within machines.

Wavy Nozzle use

Fewer leftover chips within machines.

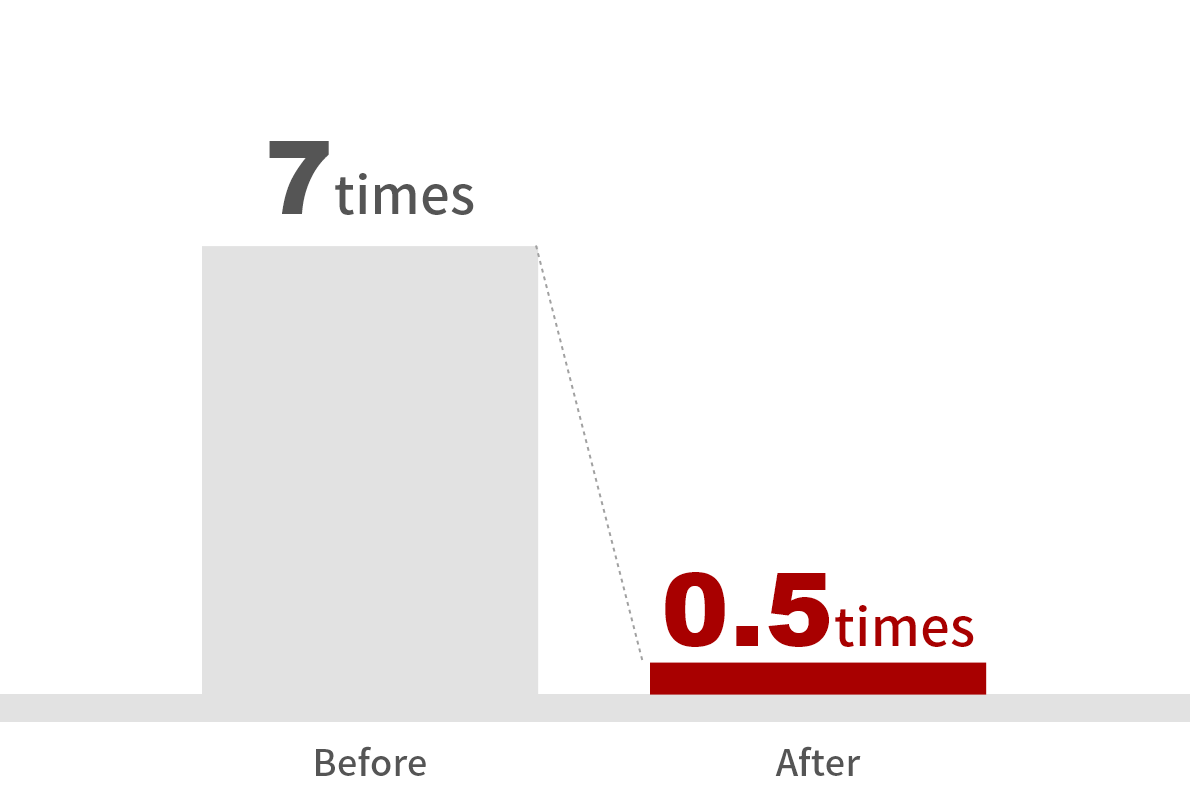

Reduced machine stoppage frequency

Machine stoppage frequency for chip removal per shift

*Cutting process

Product: Shaft, Material: SUS303

*Data based on actual company results

Improved yield rate!

Improved yield rate!

- BEFOREProducts are damaged!

- AFTERReduced scrapImproved yield rate!

- BEFOREAccuracy is inconsistent!

- AFTERReduces quality inconsistency and minimizes wasteContributes to reduced costs & effective use of manpower

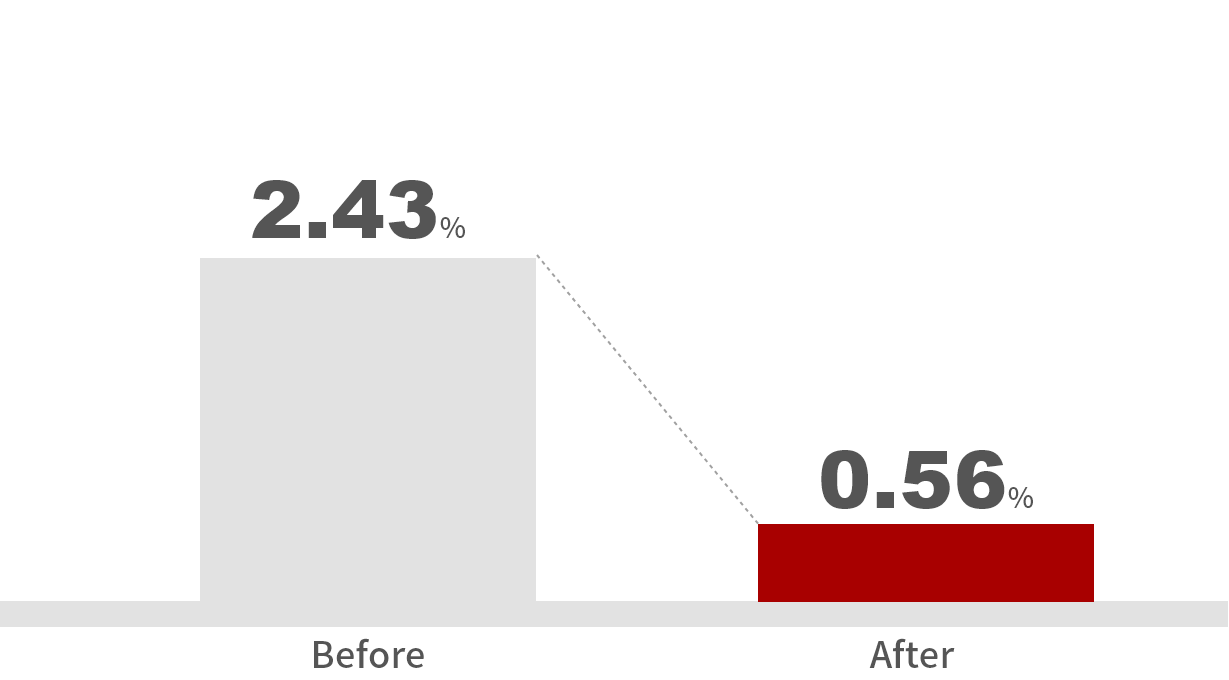

Reduces component dimension defects

Defect rate of component length

*Cutting process

Material: S45C: Dimension inspections of 3,500 parts

*Data based on client results

Reduced breakdown of cutting tools!!

Reduced breakdown of cutting tools!!

- BEFORECutting tools suddenly break down!

- AFTERReduced chip entanglement of cutting toolsRealizes longer life of cutting tools!

Fixed nozzle use

Wavy Nozzle use

A Swinging nozzle eliminates chips and related issues

An innovative idea of guiding chips in one direction and making them less likely to become entangled…

To address “costs/efficiency/work processes”

at metal machining sites.

MinebeaMitsumi's Wavy Nozzle transforms the productivity

and work processes of manufacturing sites.

PLAY MOVIE

PLAY MOVIE

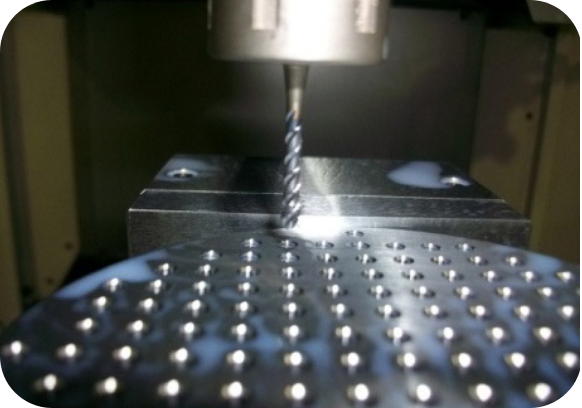

Wavy Nozzle - Programmable Coolant System (Machining center benefits)

Control metal chips and increase profits.

Our programmable coolant system helps solve machining problems.

Improve productivity, yield and tool life!

MinebeaMitsumi's Wavy Nozzle Introduction Video. PLAY MOVIE

PLAY MOVIE

Wavy Nozzle - Programmable Coolant System (NC lathe benefits)

Control metal chips and increase profits.

Our programmable coolant system helps solve machining problems.

Improve productivity, yield and tool life!

MinebeaMitsumi's Wavy Nozzle Introduction Video. PLAY MOVIE

PLAY MOVIE

Programmable Coolant System "Wavy Nozzle 2"

Optimize chip removal using an oscillating and programmable coolant delivery system equipped with targeted operating modes.

Powerful chip removal in a compact package. Significantly improve yields!