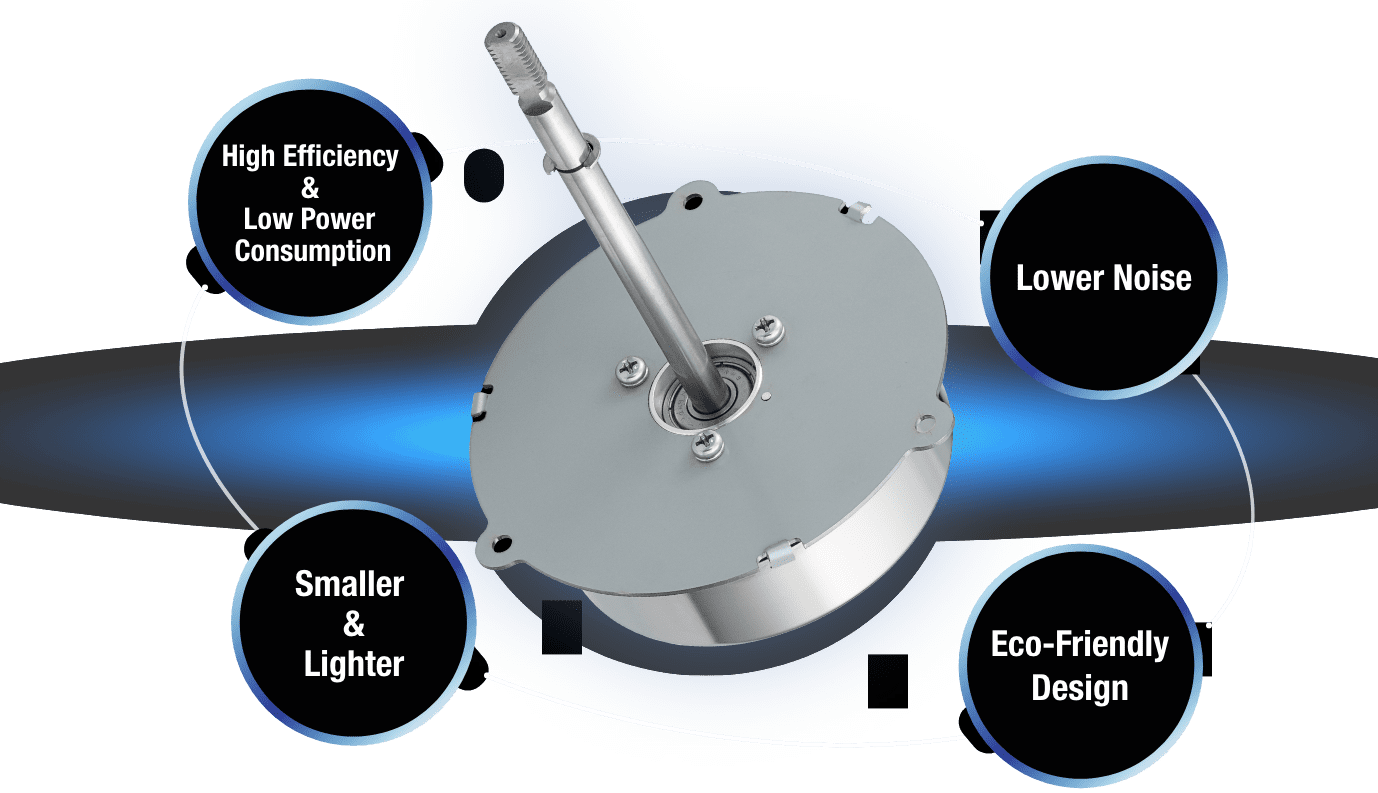

High Voltage DC Brushless Motor

Four Features-

Low Power ConsumptionAchieve higher efficiency (=lower power consumption) with 7% higher KT (torque constant) which enables to obtain same torque with less current compared to the conventional mold inner motor.

![]()

-

The motor is quieter in the low speed range and generates lower noise in the high frequency band compared to the conventional mold inner motor (*1) due to optimized vector control and magnetic circuit design.

The noise from a motor mounted in an air purifier by MinebeaMitsumi was compared with the noise from the conventional mold inner motor

-

The use of a steel plate cover makes it easier to disassemble the motor and remove parts, enabling the motor to be recycled while the conventional mold inner motor (*1) cannot.

-

The motor is lighter and thinner than the conventional mold inner motor (*1).

Other Features

-

The motor is designed to have longer life even if a high load equivalent to an output of 70 W is added to the shaft tip.

-

The motor installed directly on a set using a plate simplifies the mounting structure.

-

The motor's rotating speed can be controlled according to CLOCK, PWM and VSP signal.

Available by changing software alone -

Standard features include over/undervoltage protection, current limiting and lock detection.

ContactClick here for specifications, technical information, customization and price inquiries

High Voltage DC Brushless Motor

Example of use-

![]()

Air purifier

-

![]()

Ventilating fan

-

![]()

Range hood

About MinebeaMitsumi

MinebeaMitsumi Inc. is a "comprehensive partnering" precision parts manufacturer, creating new value-added products in various fields by combining diverse technologies and products in the machined components business, such as bearings; the electronic devices business, such as electronic devices and small motors; and the automotive components, industrial machinery, and housing equipment businesses.

With the top share in the global market for miniature ball bearings and stepping motors, we support manufacturing around the world.

Contact

Inquire here for specifications, technical information, and sales price inquiries.